PCB vs. PCBA – What’s the Difference?

PCBs and PCBAs are both necessary components of electronic devices. While their names are similar, they are two distinct items. What is the difference – and which do you need?

What is a PCB?

A PCB (printed circuit board) is typically made from fiberglass, composite epoxy, or another laminate material, onto which microprocessor chips, transistors, and other electronic components are connected. However, they do not contain any of the components that connect to the board. The conductive pathways between components are printed or etched onto the board, typically with copper foil.

Most PCBs are about six inches per side. PCBs can be single-sided, with one copper layer: double-sided, with two copper layers, or multi-layer, with more than two conductive layers. With more layers, the PCB can have a higher density of components and a more complex design. PCBs can be rigid, flexible, or flex-rigid, and have conductive contact fingers on their outside edges.

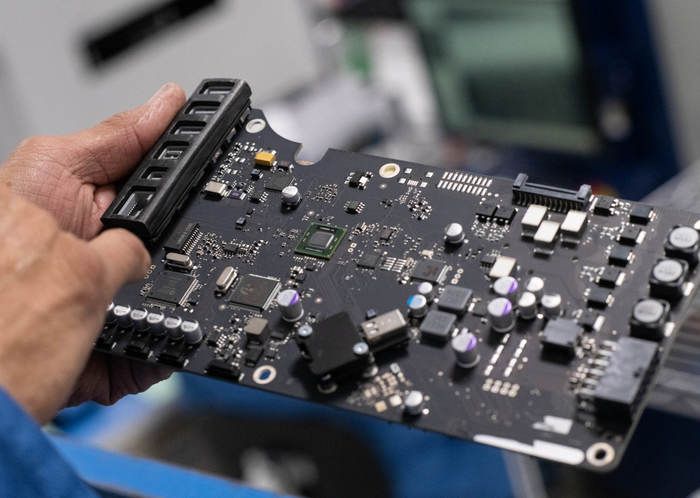

What is a PCBA?

A PCBA (printed circuit board assembly) is a PCB after all the electronic components have been installed and connected. Consider a PCB to be a bare circuit board and a PCBA to be the finished board.

There are two primary ways that components can be connected to the circuit board:

- Surface-mount technology (SMT) involves soldering the components directly to the surface of the board

- Through-hole technology requires inserting connecting leads through holes drilled in the board and then soldering them into place

Through-hole is an older technology that involves much manual assembly. It creates a stronger connection and is useful for situations where durability is important. SMT is a newer technology that can be highly automated and enables more connections to a board. It is useful in applications that require complex circuitries and smaller boards.

PCB vs. PCBA – Which do You Need?

PCBs and PCBAs are two steps of a larger process. By itself, a PCB is non-functional. The PCB must have electronic components installed to become a PCBA, which can then be inserted into electronic equipment and used as designed.

Choose Sonic for All Your PCB and PCBA Needs

Whether you require a PCB design or a PCBA assembly, turn to Sonic Manufacturing Technologies. Located in the Bay Area, in Fremont near San Jose, Oakland, Silicon Valley, and Sacramento, we have more than 20 years of experience with PCBs and PCBAs and offer a full range of services, including:

- Final product assembly

- Box builds for protecting and wiring PCBAs with the end products

- Cable harness assemblies that include PCBAs as part of the component

We can also handle your materials management. We are a one-stop-shop for all your printed circuit board needs.

Contact Sonic Manufacturing Technologies online, by phone at (510) 580-8500, or by emailing us at sales@sonicmfg.com for all PCB and PCBA needs.

CALL FOR A QUOTE

(510) 580-8500

OR EMAIL:

Sales@Sonicmfg.com