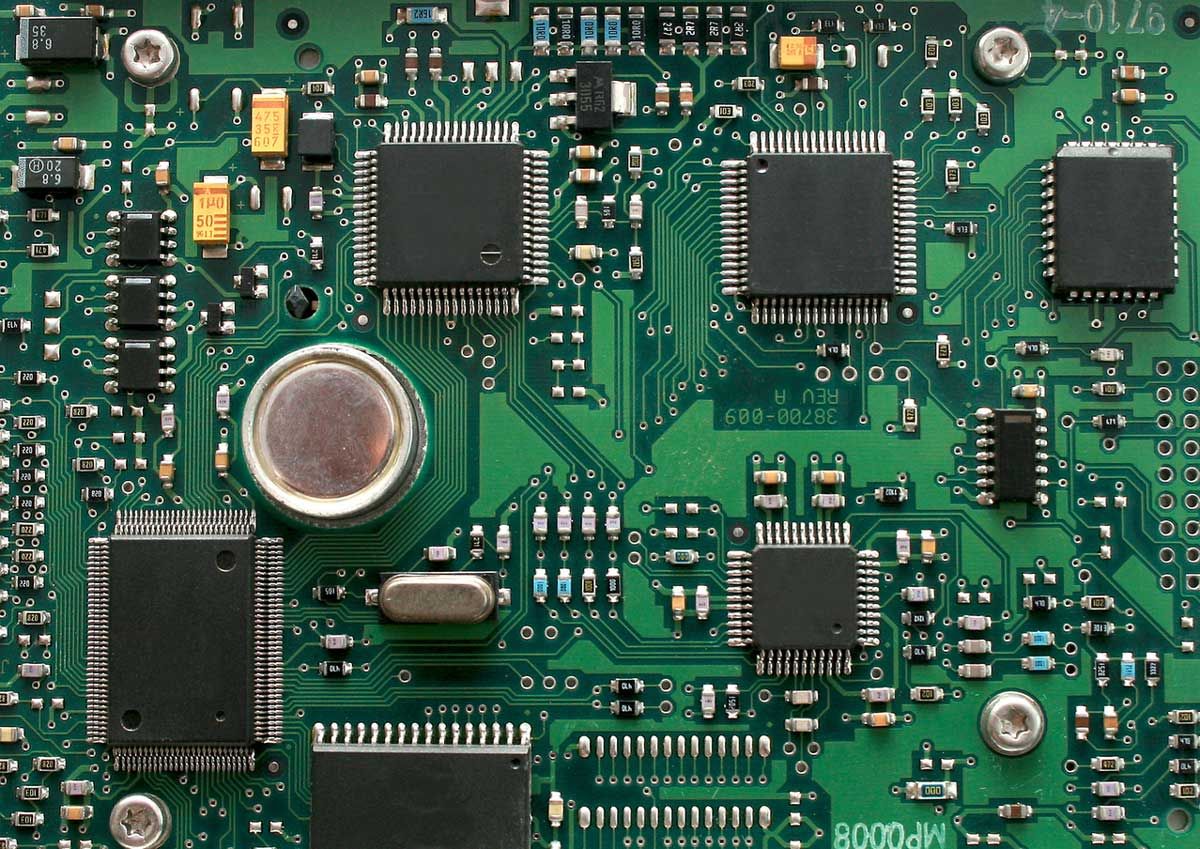

How to Improve Quality Control in PCB Manufacturing

Quality control is crucial in the printed circuit board (PCB) manufacturing process, as it ensures the reliability, functionality, and performance of electronic devices. By implementing effective quality control measures, manufacturers can minimize defects, improve customer satisfaction, and reduce costly rework or product recalls.

Let’s discuss some of the key strategies we use to enhance quality control in PCB manufacturing. These practices ensure that you will get the high quality and reliable PCBs you are counting on.

Design for Manufacturability (DFM) Guidelines

Design for manufacturability (DFM) plays a vital role in quality control. By following DFM guidelines during the design phase, we reduce the likelihood of manufacturing errors and improve overall product quality. To be effective, it’s important for design engineers and manufacturing teams to collaborate.

Key DFM Guidelines:

- Minimize the use of complex layouts and features that may lead to manufacturing challenges or defects.

- Ensure proper spacing between components to prevent shorts or electrical interference.

- Follow industry-standard design rules to avoid issues related to trace widths, spacing, and solder mask clearances.

- Consider thermal management and proper grounding to prevent overheating or electrical issues.

Automated Optical Inspection (AOI) Systems

Automated optical inspection (AOI) systems play a significant role in quality control during PCB manufacturing. AOI systems use advanced imaging technology to inspect PCBs for defects, including missing or misaligned components, soldering issues, and incorrect polarity. By employing AOI systems, manufacturers can identify and fix potential defects early in the production process, reducing the likelihood of defective PCBs reaching the market.

Statistical Process Control (SPC)

Statistical process control (SPC) involves collecting and analyzing data throughout the PCB manufacturing process to identify trends, detect process variations, and ensure consistency in quality. By monitoring key quality parameters such as trace width, impedance, soldering temperature, and component placement accuracy, manufacturers can identify any changes from the defined standards and take corrective actions, if needed.

Thorough Testing and Inspections

Comprehensive testing and inspection are crucial for quality control in PCB manufacturing. Implementing functional testing, in-circuit testing (ICT), and electrical testing can help identify potential defects or performance issues. Additionally, conducting visual inspections and solderability testing ensures the physical integrity of the PCB, such as proper soldering, component alignment and cleanliness.

Supplier Quality and Traceability

Quality control extends beyond the manufacturing facility to the supply chain. This is why it’s important for manufacturers to collaborate closely with component suppliers to ensure the quality and authenticity of the materials used in PCB production. For instance, Sonic Manufacturing implements rigorous supplier qualification processes and establishes clear quality standards for components.

Employee Training and Skill Development

Another aspect to consider is the expertise of the manufacturing team. When PCB manufacturers invest in ongoing training and skill development programs, they keep their teams on top of the latest processes, IPC-A-610 standards, soldering techniques, and quality control methodologies. This is the culture you can expect at Sonic Manufacturing.

Quality Data

Sonic keeps detailed records of data including defects, rejection rates, corrective actions, and customer feedback. We use this data to identify recurring issues, root causes, and areas for improvement to allow continuous improvement in our PCB manufacturing quality.

PCB Quality Assurance at Sonic Manufacturing

Improving quality control in PCB manufacturing is essential to ensure the reliability and functionality of electronic devices. Sonic Manufacturing is the largest EMS in Silicon Valley, providing consistently high quality PCB/PCBA services. We have a well-defined, systematic evaluation system that ensures the highest standards of quality are being met. Contact us today for a free quote.

CALL FOR A QUOTE

(510) 580-8500

OR EMAIL:

Sales@Sonicmfg.com