What are Stitching Vias in Printed Circuit Boards?

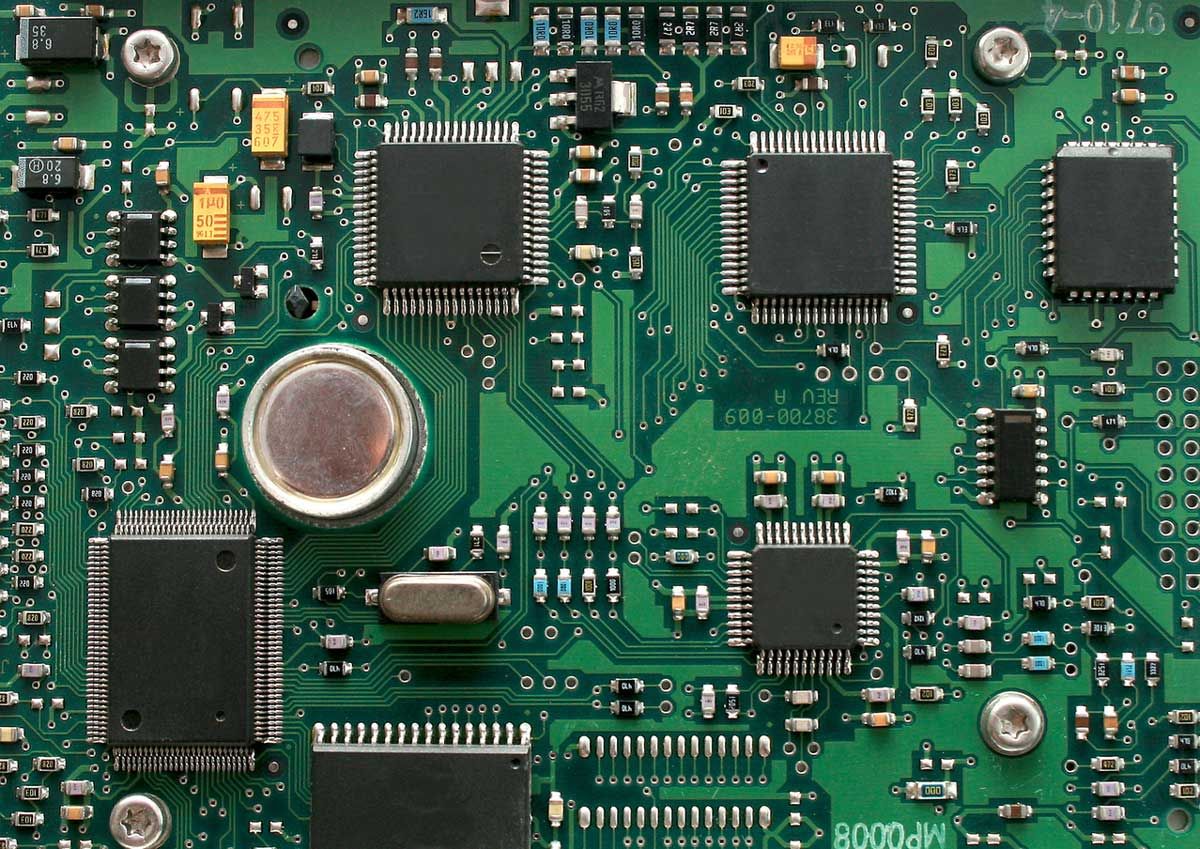

Stitching vias, also known as via stitching, are a design practice where a series of vias are strategically placed around the perimeter of a ground plane or a signal trace on a PCB. These vias connect the top and bottom layers of the board, creating a continuous conductive path.

The purpose of stitching vias is to enhance the electrical and thermal conductivity of the PCB and to improve signal integrity and reliability, especially in high-frequency and high-speed applications. Let’s learn more about stitching vias and when we use them in a PCB.

Importance of Stitching Vias

Stitching vias are basic structures that consist of a periodic array of vias grounded across the PCB. This allows them to make connections across layers. There are several reasons to use stitching vias.

For one, they reduce ground bounce and ensure stable signal references. They also act as a shield against electromagnetic interference (EMI) and radio frequency interference (RFI). By creating a continuous conductive path, stitching vias reduce the loop area, minimize the chances of signal distortion, and ensure that signals reach their destination without degradation.

In addition to their electrical benefits, stitching vias also improve thermal conductivity. They help dissipate heat from active components, preventing localized overheating and ensuring consistent performance, especially in devices susceptible to thermal stress.

Furthermore, stitching vias enhance the mechanical stability of PCBs, reducing the risk of via failures due to vibrations and mechanical shock. This can happen in some electronic devices, particularly those in automotive and aerospace applications.

Best Practices for Implementing Stitching Vias

When adding stitching vias to a PCB, it’s important to place them around the edges of critical components, high-speed signal traces, and ground planes. Strategic placement ensures effective shielding and improved signal integrity. We choose the appropriate size and spacing of stitching vias based on the specific requirements of your application and the PCB’s material.

Sonic Manufacturing has extensive experience with stitching vias and recognizes the importance of them in PCB design. As electronic devices continue to advance in complexity and speed, the need for stitching vias increases. To learn more about how we can help you achieve superior performance and reliability in your electronic application, contact Sonic Manufacturing today.

CALL FOR A QUOTE

(510) 580-8500

OR EMAIL:

Sales@Sonicmfg.com