Top 5 Things to Know when Designing a PCB

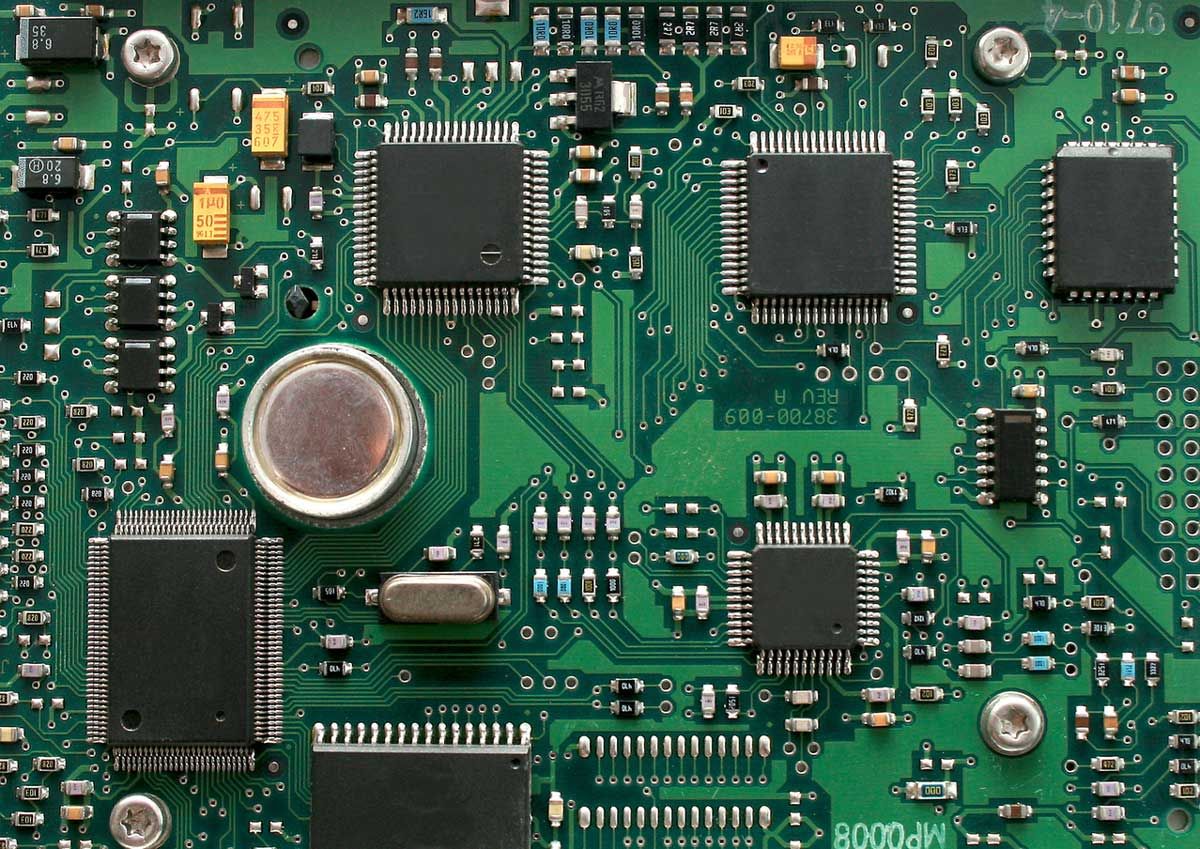

Building a printed circuit board (PCB) is a complicated task. These boards have a lot of associations between layers, components, and circuitry and they must all be properly handled. Otherwise, the PCB may not function correctly. Fortunately, there are simple practices that PCB designers follow to make the process more accurate, manageable, and efficient.

Below are the top five considerations that PCB manufacturers keep in mind when designing a printed circuit board.

1. Component Placement

The first step is to choose the correct components, which include parts like resistors, capacitors, transistors, switches, and LEDs. Placing them in an ideal position on the circuit board is even more important, as there are many factors to account for.

For example, placing the components too close together can cause issues with overheating, traces, and resistance. However, you don’t want the components to have too much distance, as the PCB needs to be small and lightweight. By creating a circuit diagram and drawing the schematics, PCB designers can design a board layout that is practical and efficient.

2. Traces

Traces are combined networks of copper, fuse, wiring, and insulation. They are responsible for sending signals throughout the PCB. Ideally, the goal is to keep traces as short as possible while still leaving enough room to prevent interference. The rule of thumb is to leave a gap of 0.007 to 0.0010 inches between each adjacent trace and pad.

3. Overheating

Another issue that needs to be accounted for is overheating. When electricity flows through PCBs, the parts heat up and can cause lasting damage, especially if the design is of poor quality. To avoid overheating, it’s important to factor in component distance and leave enough space for heat venting techniques.

4. Spacing

One of the most important aspects of PCB design is proper spacing between parts. There must be enough space between traces and components while accounting for extra layers and other necessities for the board. At the same time, PCB designers must ensure the board stays the desired size.

5. Prototyping

Prototyping is a draft process where the design team implements ideas into tangible forms. This allows designers to test the practicality of the current design and think about how users might think and feel about the product. Plus, a prototype allows designers to identify potential issues so that they do not go into the final product.

PCB Assembly and Manufacturing Services

These five things are essential before designing a printed circuit board. Sonic Manufacturing Technologies is a PCB manufacturer with everything you need under one roof. We provide in-house board layout, prototyping, and new product introduction (NPI) through full production in as little as five to ten days. To learn more about our services, contact our team today.

CALL FOR A QUOTE

(510) 580-8500

OR EMAIL:

Sales@Sonicmfg.com