What are Multilayer Printed Circuit Boards?

Multilayer printed circuit boards (PCBs) are the unsung heroes that power our modern devices. These intricate creations have revolutionized the way we design and manufacture electronics, enabling us to pack more functionality into smaller spaces while maintaining efficiency and reliability.

Let’s dig deeper into the world of multilayer PCBs, exploring what they are, how they work and the benefits they bring to the electronic landscape. If you need multilayer PCBs, be sure to contact Sonic…

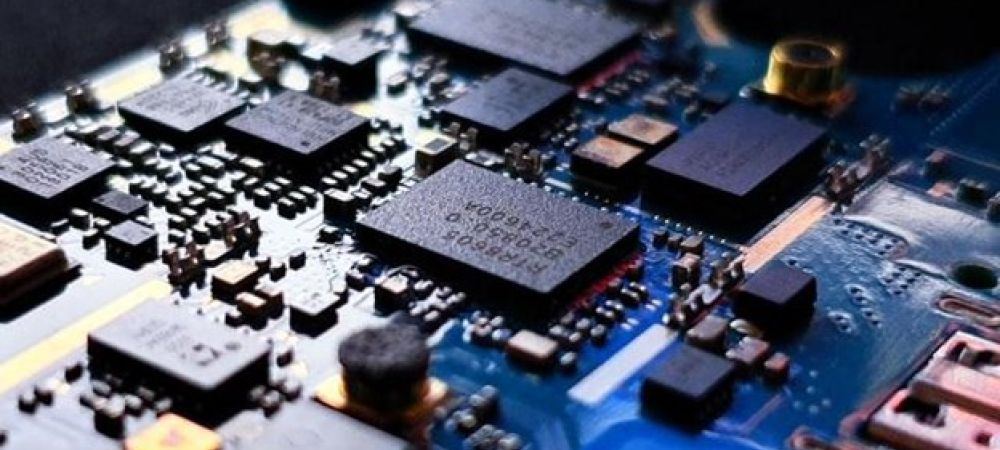

Understanding the Role of Passive Components in PCBs

Behind the sleek and sophisticated devices that we rely on for everyday convenience and entertainment lies a world of intricate circuitry. Among the key players in this realm are passive components – elements that quietly ensure the smooth functioning of electronic circuits.

Let’s unravel the mystery surrounding passive components in printed circuit boards (PCBs), exploring what they are, how they work and why they are indispensable to modern electronics.

What are Passive Components, E…

Exploring the Role of Printed Circuit Boards in IoT Devices

The internet of things (IoT) is changing the way we interact with the world around us – and it’s not expected to slow down. From smart homes to wearable devices, IoT technology has the potential to revolutionize the way we live our lives. But, as with other types of technology, IoT devices need certain elements to work effectively. One of the most significant is a printed circuit board, or PCB.

Let’s explore the role of PCBs in IoT devices and why they are essential.

What is a Printed …

Understanding Signal Integrity in Printed Circuit Board Layouts

Signal integrity is a critical factor in the design of any electronic system, including printed circuit boards (PCBs). A good understanding of signal integrity is important when designing PCBs, as it ensures that the circuit functions correctly and reliably. Signal integrity practices focus on identifying and fixing problems with the PCB layout that may be interfering with the signal.

Let’s learn more about the basics of signal integrity in PCB layout and why it matters to your devices.

…

The Role of PCBs in Computing and Storage

Printed circuit boards (PCBs) are an integral component of modern computing and storage systems. They allow efficient and reliable transmission of electrical signals within electronic devices. From servers and data centers to laptops and smartphones, PCBs play a critical role in powering and connecting the components that drive computing and storage capabilities.

Let’s explore the significance of PCBs in computing and storage systems and highlight their key contributions to these technolo…

CALL FOR A QUOTE

(510) 580-8500

OR EMAIL:

Sales@Sonicmfg.com