Partner with Sonic Manufacturing for Electronic Prototype Assembly Services

A prototype is an early sample, model or release of a product created to test a concept or process. It’s primarily used to evaluate a new design before a company invests in mass production. Prototypes often fail, and this shows designers where the defects are. The team then can ‘go back to the drawing board’ and refine the design. Prototypes avoid wasted time, money, and headaches and can even save lives.

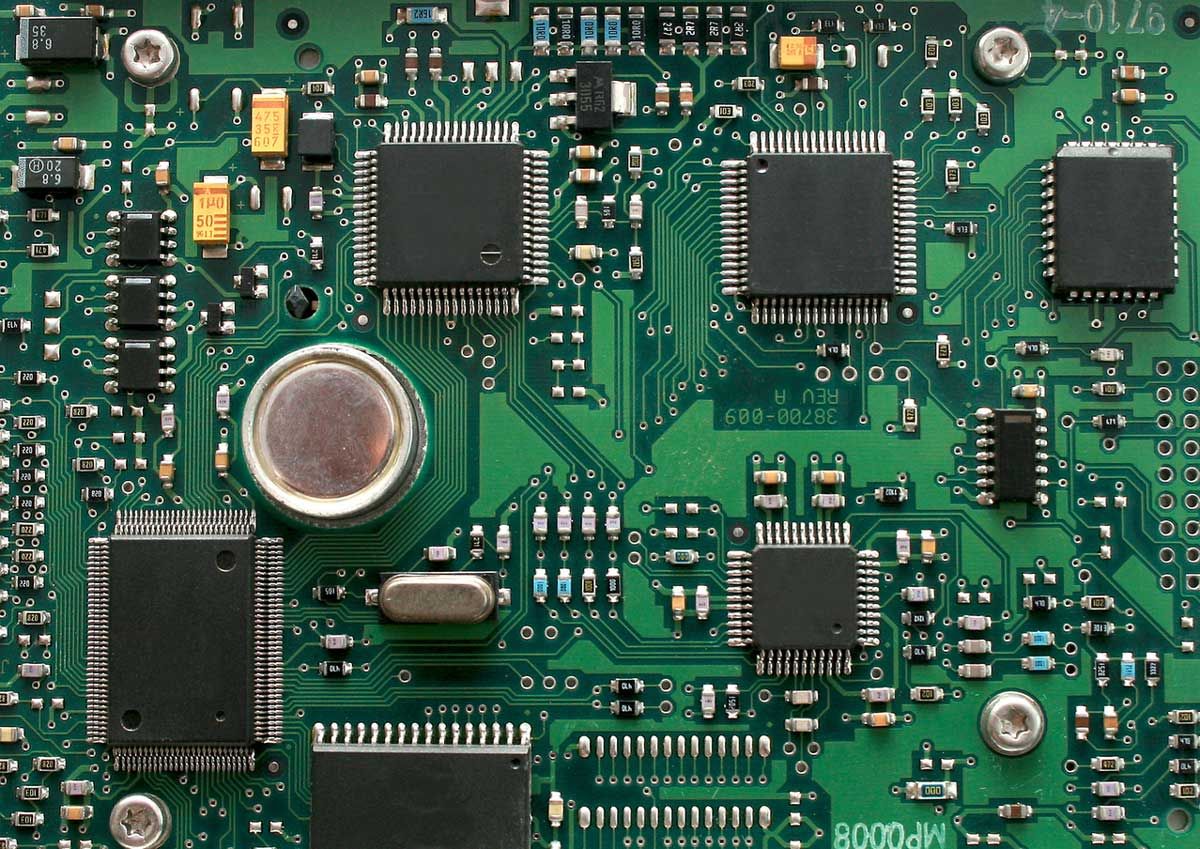

In printed circuit board (PCB) design, a prototype is the first sample that’s built to test the functionality of the design. Prototyping is a critical phase of new product development. Sonic Manufacturing Technologies is happy to partner with your manufacturing company to make the most of the electronic prototype assembly process.

Effective Prototyping for PCBs

PCB prototyping gets rid of the guesswork so you can quickly and efficiently identify potential problems. The most common prototypes are two and four-layer PCBs. They use conductive tracks to connect components. Since they are printed, there is no need for a complex wiring process, making them cheaper than traditional circuit boards.

Make sure that you have easy-to-follow documentation to ensure your design is correct. The documentation to have on hand includes:

- Templates

- Bill of materials (BOM)

- Reviews and signoffs

- Edits and deletions

- Up-to-date parts numbers

Collaborate with Sonic Manufacturing Technologies

Electronic prototype assembly is the foundation of good product development. These early stages will impact the PCB design and assembly process, so it’s important that you work with a quality manufacturer.

Sonic Manufacturing Technologies will run your prototype assemblies on established manufacturing lines to ensure manufacturability. This means that your product will stand up to the market when released. When your manufacturing company partners with us, we’ll make sure that your business gets on-line inspection and zero-defect products.

If we do find any issues or functional failures from the product design, we will work with your manufacturer to mitigate them. This will save you time and money by getting things right from the beginning. Our production line for new product assemblies helps us understand where failures are most likely to occur.

To learn more about partnering with Sonic Manufacturing Technologies, contact our team of PCB assembly experts today. Our industry leading supply chain management system ensures on-time delivery, superior service, accuracy, and reliability.

CALL FOR A QUOTE

(510) 580-8500

OR EMAIL:

Sales@Sonicmfg.com