What is PCBA Box Build Assembly?

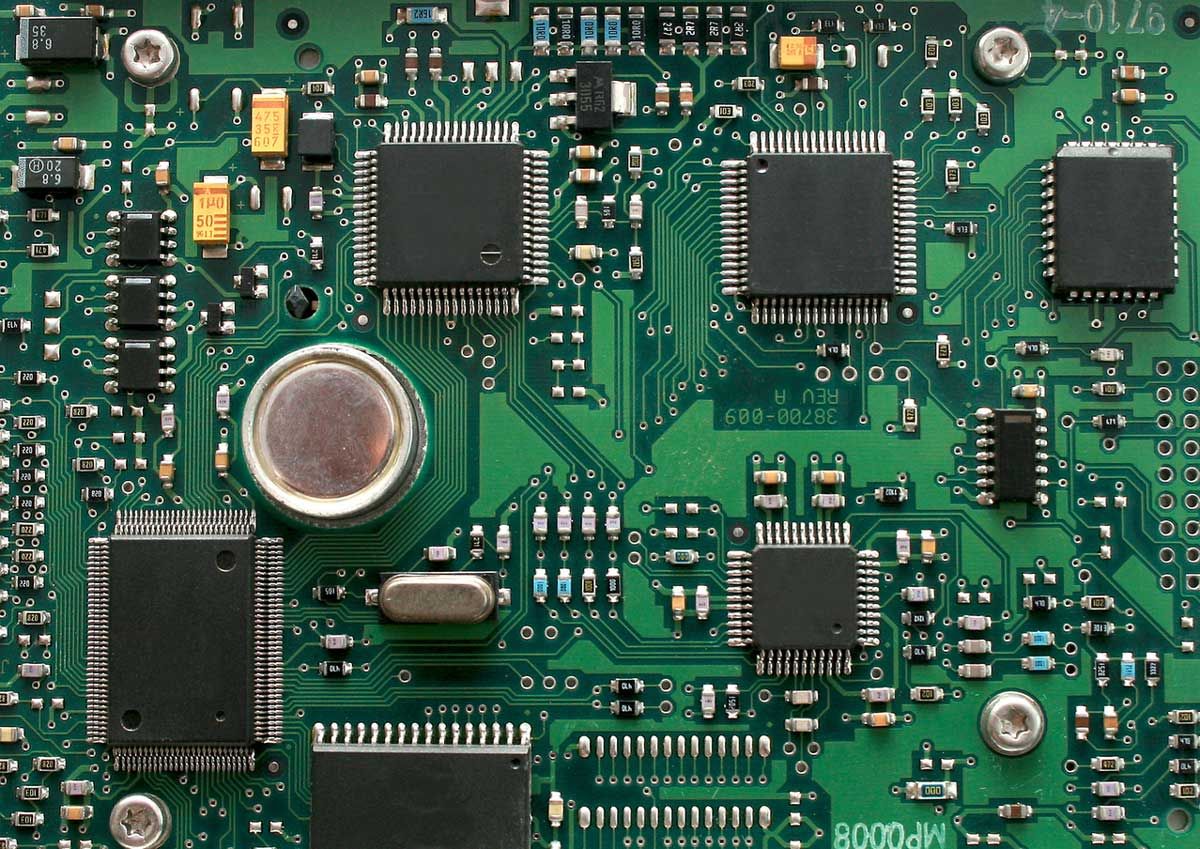

Printed circuit boards (PCBs) form the backbone of modern electronics, connecting various components and facilitating the smooth operation of devices. While the focus often revolves around the intricate circuitry and soldering of components, another crucial aspect of PCB manufacturing and assembly is the box build assembly.

Let’s delve into what box build assembly entails and its significance in the production of electronic devices.

Understanding Box Build Assembly

Box build assembly, also known as systems integration assembly, refers to the process of assembling the final electronic product. It involves designing and manufacturing the enclosure, installing the PCBA and installing cables, electrical, and pneumatic systems.

Sonic Manufacturing has an 85K-square-foot production facility that utilizes advanced production line technology for all your box build needs. Here are the components involved in box build assembly:

- Subassemblies are smaller assemblies or modules that, when combined, create the final product. These could include displays, controllers, or power supplies.

- Enclosures and housings are the physical casings or enclosures that house the assembled PCB and associated components, protecting them from external elements and providing structural integrity.

- Wiring and cabling refer to the intricate network of wires, cables, connectors, and harnesses that link various components within the device.

- Mechanical parts include mounting hardware, brackets, fasteners, and other mechanical parts required to assemble the device.

- Software/firmware installation loads the necessary software or firmware onto the device to ensure proper functionality.

Significance of Box Build Assembly

Streamlining production

Box build assembly streamlines the manufacturing process by integrating multiple components into the final product, reducing the need for separate assembly lines, and simplifying logistics.

Quality control

The assembly of the complete product allows comprehensive testing and quality control measures to be applied at the final stage, ensuring that the device functions as intended before reaching the market.

Customization and flexibility

Box build assembly enables customization and flexibility in product design. It accommodates variations in components, configurations, and functionalities tailored to meet specific customer requirements.

Time and cost efficiency

By consolidating the assembly process into a single step, box build assembly can save time and reduce production costs, minimizing handling and transportation between different assembly stages.

Sonic’s PCBA Box Build Assembly Services

In the intricate world of PCB manufacturing, the significance of PCBA box build assembly cannot be overstated. It represents the final stage where various components, subassemblies, enclosures, and software/firmware integration come together to form a fully functional electronic device.

To learn more about Sonic’s box build assembly services, contact our team today. We bring over 20 years of experience to box builds and will provide you with the highest quality service.

CALL FOR A QUOTE

(510) 580-8500

OR EMAIL:

Sales@Sonicmfg.com